High-speed mixer is a material mixing equipment widely used in many industries. It is favored for its mixing ability and wide applicability. The following is a detailed analysis of high-speed mixer:

1. Definition and Overview

High-speed mixer is a device that mixes materials quickly and evenly through high-speed rotating stirring blades. It is particularly suitable for mixing various material combinations such as solid-liquid, solid-powder, powder-powder, powder-liquid, etc., and is widely used in pharmaceuticals, food, chemicals, plastics, ceramic materials, biology, medicine, non-metallic mining, building materials, coatings, dyes, fertilizers and metal powders.

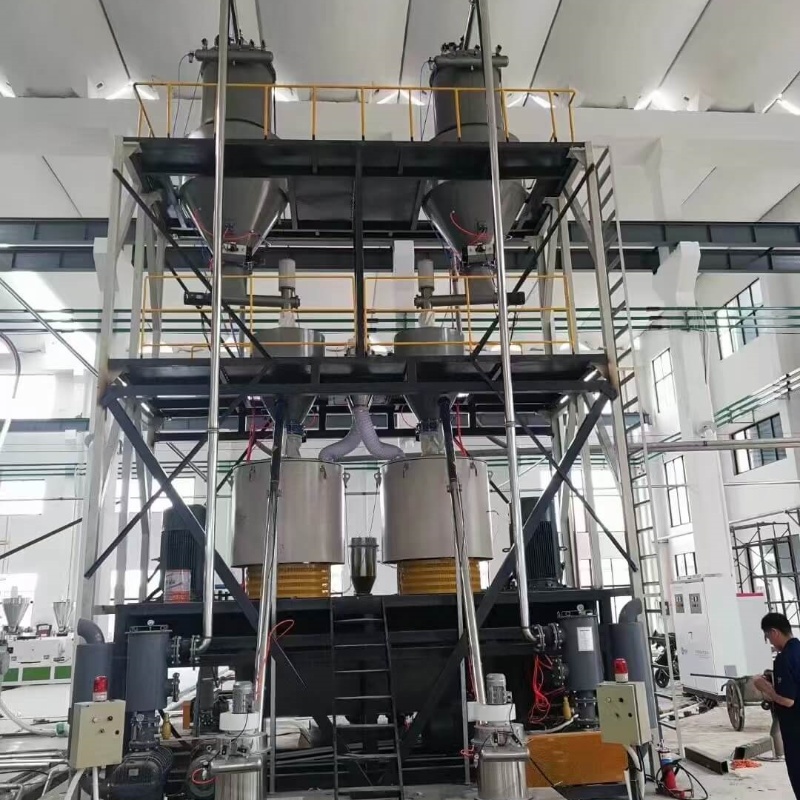

2. Working Principle

The working principle of high-speed mixer is mainly based on the mechanical effects of shear, collision and compression between materials. When the mixer is started, the main shaft drives the stirring blade to rotate at a high speed, and the material is thrown to the pot wall under the tangential motion of the blade and rises along the wall. Part of the rising material falls back to the center of the blade under the action of gravity, and the other part hits the pot cover and falls down, repeatedly forming a combination of rising motion and tangential motion, so that the materials collide with each other and cross-mix. At the same time, the collision and friction between the material and the blade, the inner wall and the material will also cause the temperature to rise rapidly, further promoting the mixing effect.

3. Structure and composition

The high-speed mixer is mainly composed of the following parts:

Mixing tank: a conical container composed of a grinding plate, a shell and a top cover, etc., used to hold the material to be mixed. The top cover is provided with a material and binder inlet, and the grinding plate structure is a jacket type for cooling water and hot water to pass through to adjust the temperature of the material during mixing.

Rotating blade: a stirring blade with a special shape, installed on the main shaft, which generates shear force and centrifugal force through high-speed rotation, throws the material to the pot wall and forms a vortex stirring.

Transmission device: It is composed of an electric motor, a belt wheel and a reduction box to provide power for the stirring blade. The electric motor often adopts a speed regulation type to meet different mixing requirements.

Discharging mechanism: a device installed on the side of the mixing tank, used to discharge the mixed material. The mechanism consists of a set of connecting rod systems, usually directly driven by a cylinder.

Temperature control device: including cooling water grid, hot water tank and circulation device, used to adjust the temperature of materials during mixing to ensure the mixing effect and product quality.

IV. Application field

High-speed mixers have shown their wide application value in many industries:

Pharmaceutical industry: used for dry mixing and wet mixing of drugs, to mix particles and powders of different components evenly, and improve the stability and quality of drugs.

Food industry: mainly used for mixing powdered food condiments and additives, etc., to evenly mix food raw materials of different particle sizes and properties, and enhance the taste and quality of products.

Chemical industry: widely used for mixing solvents, granular materials, colloids and other chemical substances to improve production efficiency and product purity.

Plastic industry: one of the commonly used equipment in the plastic processing process, used for mixing and coloring of polyvinyl chloride resins, and coloring and drying of polyethylene and polypropylene particles.

V. Advantages and characteristics

Significant mixing effect: the high-speed stirring blade can mix materials quickly and evenly.

Flexible operation: the equipment has a compact structure and is easy to operate; it is also easy to clean and maintain, extending its service life.

Wide applicability: Adapt to the mixing needs of various material combinations and meet the production requirements of different fields and industries.

In summary, high-speed mixers play an important role in multiple industries with their mixing effect and wide applicability. With the continuous advancement of technology and the continuous development of industrial production, high-speed mixers will continue to be optimized and improved to meet market demand.