Screw feeder: “porter” in industrial production

Screw feeder, as the name implies, is a mechanical device that uses the rotation of spiral blades to transport materials. It is widely used in many industries such as food, chemical, pharmaceutical, building materials, etc., and is one of the indispensable links in the production line.

Working principle

The working principle of the screw feeder is actually very simple: a shaft with a spiral blade rotates in a closed pipe, and the material is transported forward along the pipe under the push of the spiral blade. By adjusting the speed of the spiral blade and the inclination of the pipe, the conveying speed and flow rate of the material can be controlled.

Structural composition

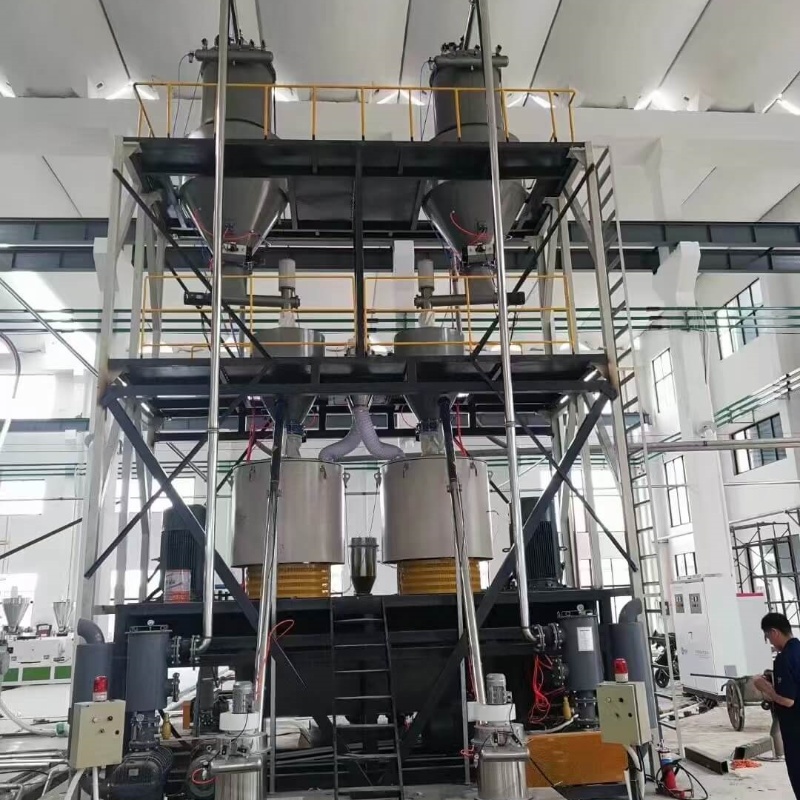

The screw feeder is mainly composed of the following parts:

Drive device: Usually an electric motor is used to provide power for the spiral blade.

Spiral blade: The spiral blade is the core component of material transportation.

Casing: A closed pipe that wraps the spiral blade to prevent material leakage.

Bearing: A component that supports the rotation of the spiral blade.

Feed port and discharge port: The inlet and outlet of the material.

Features and Advantages

Screw feeders have the following outstanding features and advantages:

Continuous conveying: Screw feeders can achieve continuous and uniform conveying of materials and improve production efficiency.

Strong adaptability: It can convey a variety of materials, including powder, granular, small blocks, etc.

Good sealing: The closed pipeline effectively prevents material leakage and ensures the cleanliness of the production environment.

Simple structure: Easy to install and maintain.

High controllability: By adjusting the speed and inclination, the material conveying amount can be accurately controlled.

Application areas

Screw feeders are widely used in industrial production, mainly including:

Food industry: Used to convey powdered materials such as grain, flour, sugar, and block materials such as meat and vegetables.

Chemical industry: Used to convey various chemical raw materials and finished products.

Pharmaceutical industry: Used to convey pharmaceutical raw materials and finished products.

Building materials industry: Used to convey building materials such as cement, sand and gravel.

Feed industry: Used to convey feed raw materials.

Precautions

When using a screw feeder, you need to pay attention to the following points:

Material characteristics: Different materials have different requirements for screw feeders, so choose the appropriate spiral blades and pipe materials.

Conveying capacity: Choose the appropriate screw feeder model according to production needs.

Maintenance: Regularly inspect and maintain the screw feeder to extend its service life.

Summary

As an efficient and reliable conveying equipment, the screw feeder plays an important role in modern industrial production. With the continuous advancement of technology, the screw feeder has been continuously optimized in structure, performance and application, providing a strong guarantee for various production processes.