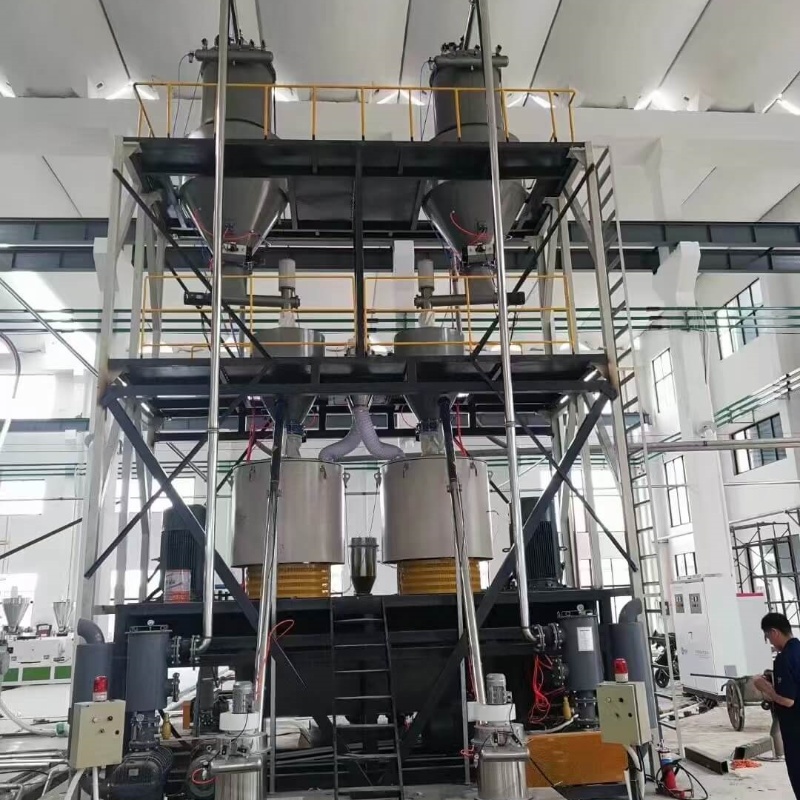

In the fast-paced plastic processing industry, efficient and reliable material feeding is crucial to maintaining high productivity. The Spiral Feeder is a specialized auxiliary device designed to transport granular or powdered plastic raw materials through a spiral conveying mechanism, ensuring continuous feeding into equipment like injection molding machines, extruders, and other processing machinery. Widely recognized for its efficiency, cost-saving potential, and stability, the Spiral Feeder is an indispensable part of modern plastic production lines.

Working Principle of the Spiral Feeder

The core function of the Spiral Feeder revolves around the spiral conveying mechanism, which operates based on the following steps:

-

Spiral Conveying: The motor drives the spiral shaft through a coupling, which rotates and pushes the raw material from the hopper toward the front of the system in a continuous manner.

-

Material Transport via Feed Tube: The material is propelled by the spiral blades within the feeding tube, ensuring smooth and consistent forward movement toward the target hopper.

-

Level Control: To ensure uninterrupted operation, the Spiral Feeder is often equipped with automatic level sensors. When the material reaches the preset level in the hopper, the feeder automatically stops feeding. When the level drops below the set point, the feeder restarts, ensuring a consistent material flow.

-

Dust Control: To reduce environmental contamination, the Spiral Feeder is designed with dust-proof devices at both the material inlet and outlet. This feature prevents dust pollution, thereby enhancing both the working environment and the lifespan of the machine.

Advantages of the Spiral Feeder

-

Increased Efficiency: The Spiral Feeder optimizes the material feeding process, reducing manual labor and significantly increasing the overall production efficiency.

-

Stable Production: With automatic level control and continuous feeding capabilities, the Spiral Feeder ensures a stable material supply, minimizing disruptions in production.

-

Cost-Effective: By automating the feeding process, the Spiral Feeder reduces the need for manual labor, leading to significant cost savings for manufacturers.

-

Environmentally Friendly: Equipped with dust-proof systems, the feeder helps minimize environmental pollution, making it a sustainable choice for modern production lines.

-

Versatile Applications: Primarily used in plastic processing equipment such as injection molding machines and extruders, the Spiral Feeder is also suitable for other industries requiring reliable material transport, such as rubber, chemical processing, and food production.

Applications

The Spiral Feeder is indispensable in the following industries:

- Plastics: Ensures smooth material feeding into injection molding machines and extruders, enhancing production efficiency.

- Rubber Processing: Facilitates efficient feeding of rubber compounds in manufacturing lines.

- Chemical Industry: Ideal for transporting powders and granular chemicals.

- Food Processing: Ensures accurate and hygienic feeding of ingredients in food production.

Conclusion

The Spiral Feeder is a game-changer for any production line that requires efficient, continuous material feeding. Its reliable design, low maintenance, and cost-effective operation make it a top choice for industries such as plastics, rubber, and food processing. With its ability to optimize material transport, ensure stable production, and reduce labor costs, the Spiral Feeder remains an essential tool for enhancing productivity and maintaining high standards in manufacturing.